Shearling Leather Coats

from

Dann Clothing

Private

Stock

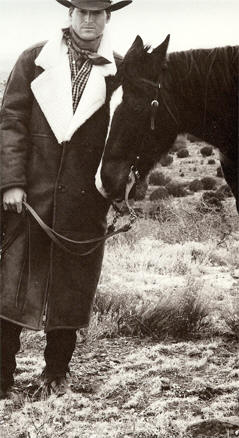

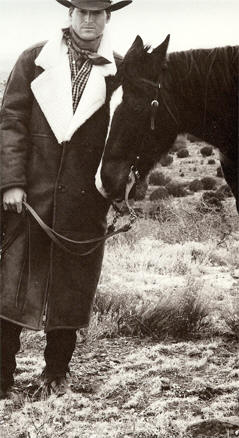

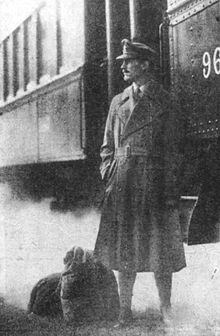

We love the Mountains.....the winter snows.......the

Holidays......Old John Wayne movies....

and all these things come to mind when we think of

Shearling ! But keep in mind---

these would look fantastic in New York City, as well !

It can fade in and out of the fashion

cycles...........but the purists always appreciate its

timeless style and taste........the soft hand of the

leather.....the rich shearling wool. Please read more about our coats at the

bottom of the page.

We look forward to sending you one (or more !) of these

! And what a dramatic gift !

Dennis & Joan

|

A shearling

is a lambskin garment finished on the outside as a suede finish or a

napalan (leather-like) finish. The wool is still

attached to the pelt, i.e. shearling. All skins are from Iceland and

Spain....The cold climate and long Icelandic winters have produced a

particularly thick fleece and hide...the finest available.......and

finished into coats by craftsman who have made these beautiful coats

for decades.

Please see our notes on sizing at bottom of page.

Each style offered in both Spanish and in Icelandic Shearling.

Spanish Shearling is absolutely the finest you can buy. It is a

little more lightweight and the wool side is very, very soft and

silky. The Icelandic is a little heavier....wool is soft but not as

soft. Once you place your order, we will be in touch by phone to

reconfirm size, etc.............

this coat will

be made to order.....off of the existing patterns shown.

We can make length or width

changes....but not DESIGN changes.

We are not able to accept returns or cancellations on Custom Coats.

Please note....leather skins can have some variations in color from

our photos and from one skin to the next as this is a completely

Natural product....not a manufactured one...making your coat truly

one of a kind. Our craftsmen are very particular about the skins

they use ! We are very proud of the work they do...and think you

will be pleased as well. We have been offering these coats now for a

number of years....are very careful about sizing.....and have had so

many very happy customers with the final product. It has really been

thrilling. We have shipped them all over the world.

For

additional sizes visit Dann Shearling Big and Tall

Dennis |

|

Will be made

to order.....off of the existing patterns shown.

We can make length or width

changes....but not DESIGN changes.

|

|

|

|

|

A great coat ! Generally we make this in a 52"

length but can be made to any length. This is a coat for a Big or

Tall Man, however, as it is "A lot of coat !". Gorgeous shawl collar

shearling collar....shearling cuffs. No Vent. Bag Pocket. |

|

|

|

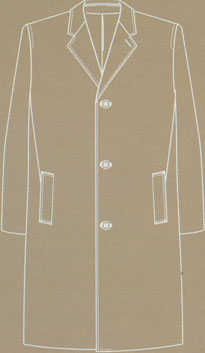

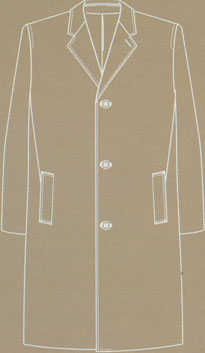

An unbelievable coat ! Just like a Dress

Topcoat.....but in rich Shearling. Available in Black, Antelope,

Cognac, Brandy, Deep Spanish Brown.

Generally we make this in a 52" length but can be

made to any length. This is a coat for a Big or Tall Man.

Notch Collar Label. Finished Cuff on the sleeve. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A word about our coats from our Shearling Expert

Craftsman......

It all begins with the excellence of skins imported from

Spain and Iceland. Matching is the first inspection step of many that goes

into the construction of a shearling garment. This process demands a keen

eye to sort the skins carefully (per garment), while matching them for

consistency in color, texture, and thickness. Plus, it takes a special

talent to determine the suitability of a particular skin for the style that is

being cut. Cutting is both an art and a craft. You need to

have a keen eye and a steady hand. Our cutters have perfected the ability

to know the part of the skin that works best for each part of the garment.

Skiving is the next step which means that the fur needs to be shaved off of the

skin to enable flat seams for construction. Sewing and assembly call for

special dexterity, particularly when setting the sleeves and collar.

Likewise to correctly join the garment and attach zippers requires unique

skills. Finally, we sew on the buttons so that the line up is perfect with

no bubbling or waving. Brushing and combing are done at this point.

Final inspection is then performed on each garment for skin quality, color

match, and seam work. Finishing equals a beautiful product with instant

hanger appeal, ready for shipping. We make your coats FOR YOU when we

get your order so we want to be sure. Here is our size chart !

| Men's Sizing |

XS |

S |

M |

L |

XL |

|

| Back Length |

34" |

34.5" |

35" |

35.5" |

36" |

|

| Chest |

34-36" |

38-40" |

42-44" |

46-48" |

50-52" |

|

| Sleeve Length from Center of

Back |

33" |

34" |

35" |

36" |

37" |

|

For sizing mens jacket sizes:

Measure around your chest. This corresponds with the chest size on the

chart. If you are over 6 feet 4 inches, you will probably need a tall size.

Note: Dann Shearling coats are sized as outerwear, so are 1 size larger that

most coats. |

Don't see your size ?? We have Big & Tall...........up to 4XL

!

Dann Private Stock Big

& Tall Shearling

Dann Shearling & Leather Shop

Complete collection

of jackets, Shearling......

Andrew Marc Coats

Viyella Solid and

Plaid Shirt Collection

The Croc Shop from Dann Clothing

Dann Cashmere Shop

Engraved

Sterling Silver Collection from Dann

The

Denim Shop from Dann

Sheepskin

Slippers

from

Dann Men's Clothing

Winter Overshoes for Men

Shoe and Boot

Protectors

Adventure Bags

from Dann Clothing

Bass Cocktail Glasses

Loop Optic Handblown Barware !

Pure

Cashmere Scarves

Dann Private Stock

Overcoats

100% Pure Cashmere

Cedar Hangers

Will Leather Goods

Hudson's Bay Point Blankets

Pinecone Barware

Loop Optic Handblown Barware !

Dann Mens Coat Collection

.JPG)

Peccary Leather Gloves from Peru

.JPG)

Baby Alpaca Bomber

Jacket

Drop us a line!

Our Shearlings begin with

the excellence of skins we import from Spain and Iceland. Matching

is the first inspection step of many that goes into the construction of our

shearling garment. This process demands a keen eye to sort the skins

carefully (per garment), while matching them for consistency in color, texture,

and thickness. Plus, it takes a special talent to determine the

suitability of a particular skin for the style that is being cut. Cutting

is both an art and a craft. You need to have a keen eye and a steady hand.

Our cutters have perfected the ability to know the part of the skin that works

best for each part of the garment. Skiving is the next step which means

that the fur needs to be shaved off of the skin to enable flat seams for

construction. Sewing and assembly call for special dexterity, particularly

when setting the sleeves and collar. Likewise to correctly join the

garment and attach zippers requires unique skills. Finally, we sew

on the buttons so that the line up is perfect with no bubbling or waving.

Brushing and combing are done at this point. Final inspection is then

performed on each garment for skin quality, color match, and seam work.

Finishing equals a beautiful product with instant hanger appeal, ready for

shipping.